News Categories

Disposable syringes

Disposable syringes

Safety Syringes/ Auto-Disable Syringes

Safety Syringes/ Auto-Disable Syringes

Oral/Enteral Syringes

Oral/Enteral Syringes

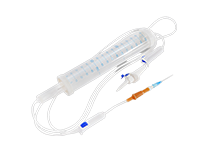

Infusion Sets

Infusion Sets

Urine Bags

Urine Bags

Urine Cups

Urine Cups

The luer slip syringe tip, which is used for blood collection and drug injections, is made of stainless steel, which is machined into a tubular structure at the beginning of production. Then, in order to make the needle seem seamless, it is necessary to weld all the seams together with laser welding, which will result in a very regular standard tubular object.

Stainless steel is not hard enough to reach the point of the needle, so in order to make the steel pipe harder, the production workers need to carry out many times the cold processing of the steel pipe, and cold processing this way the pipe can also become thinner. At this point, a pipe that was about to transform into a luer slip syringe tip was completed.

We all know that the tip of a luer slip syringe tip is pointy, so the next big step in production is how to turn two smooth tubes into sharp needles. First of all, through a rolling machine will be the steel pipe along the line cut accurately, so that we can get a length of about 5 cm of small steel pipe. These small steel pipes cut out will fall directly into a box, through the box of air pressure device vibration, so that all the small steel pipes will line up neatly, the production worker can easily pack all the small steel pipes and send them to the next processing step. With repeated rinsing and sharpening, the wheel adjusts the angle to the size of the syringe, and the tip becomes sharper, giving the luer slip syringe tip the look we normally see.

Quick Response within 24 hours!

Tel: (+)86-519-88168398

WhatsApp: +86-13961432323

Email: sale01@lelun.com

HengShanQiao Town, out of East Gate, Changzhou ,Jiangsu, China

Changzhou Medical Appliances General Factory Co., Ltd. was built in 1988, it is a modern factory specialized in producing the disposable medical appliances in China. The factory is only 1km to Hengshan entrance of Huning high-speed road and is about 20 miles to Changzhou airport. So the traffic is convenience.

The area of the factory is 40000㎡, the area of purifying workshop is 7000m, and fixed assets are about 5,000,000USD. Our main products are Disposable infusion sets, Disposable blood transfusion sets, Disposable Sterile syringe sets, latex glove, disposable infusion set, simple oxygen mask, nebulizer mask, urine cup, hernia mesh, urine bag etc. Now we can manufacture more than 200,000,000 sets per year.