News Categories

Disposable syringes

Disposable syringes

Safety Syringes/ Auto-Disable Syringes

Safety Syringes/ Auto-Disable Syringes

Oral/Enteral Syringes

Oral/Enteral Syringes

Infusion Sets

Infusion Sets

Urine Bags

Urine Bags

Urine Cups

Urine Cups

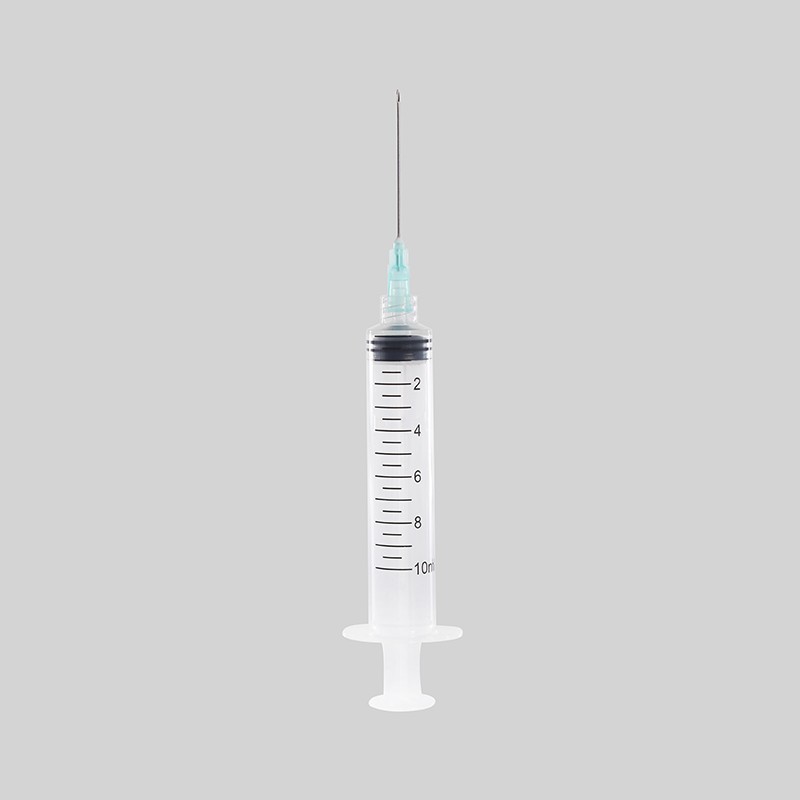

Syringes are essential medical devices used in various healthcare settings. Changzhou Medical Appliances General Factory Co., Ltd as a modern factory producing disposable medical equipment, we are committed to distributing our products to the healthcare industry.

The needle is a vital component of a syringe, responsible for delivering medication or fluids into the patient's body. It is typically made from high-quality materials such as stainless steel or medical-grade plastic. The needle's design and construction allow for precise and controlled injections. Its functions include puncturing the skin, reaching specific tissues or vessels, and delivering medication accurately. Additionally, certain needles are designed with safety features, such as retractable or anti-needlestick mechanisms, to minimize the risk of accidental injuries and needlestick infections.

The barrel is the part of the syringe that holds and stores the medication or fluids. It is commonly made of transparent or translucent materials like polypropylene or glass. The barrel's material ensures compatibility with a wide range of medications and allows healthcare professionals to visually inspect the contents and measure the precise volume needed for the injection. The barrel is marked with calibration lines or graduations, enabling accurate dosage measurement. Moreover, the barrel's smooth interior surface facilitates smooth and effortless movement of the piston, ensuring consistent medication delivery.

The piston is the movable component within the barrel of a syringe. It seals the medication inside the barrel, preventing leaks and ensuring precise dosage control. The piston is typically made of synthetic rubber or medical-grade plastics. Its primary function is to create a vacuum or pressure within the barrel, allowing for the accurate withdrawal or expulsion of medication. The piston's tight fit against the barrel's inner walls ensures the medication is delivered smoothly and evenly during the injection process. Additionally, pistons with lubricated surfaces or silicone coating can further enhance the ease of operation.

Benefits of the Core Components in Syringes:

Accuracy and Precision: The combination of a sharp needle, a transparent barrel with clear markings, and a well-fitted piston allows for precise medication measurement and delivery, ensuring accurate dosage administration.

Safety: The needle's design features, such as retractable or anti-needlestick mechanisms, reduce the risk of accidental needlestick injuries, protecting both healthcare professionals and patients.

Compatibility: The materials used in the needle, barrel, and piston are selected to be compatible with various medications, ensuring the syringe can be used for a wide range of medical treatments.

Ease of Use: The smooth movement of the piston within the barrel, aided by lubricated surfaces or silicone coating, enhances the overall ease of operation for healthcare professionals during injections.

What are the classification of syringes?

Use-based Classification

General Purpose Syringes: These syringes are commonly used for various medical purposes, including injections, aspiration of fluids, and irrigation.

Insulin Syringes: Specifically designed for insulin administration, these syringes have a smaller capacity and are calibrated in units suitable for insulin dosage.

Tuberculin Syringes: These syringes are used for administering small doses of medication, particularly for tuberculosis testing and other diagnostic purposes.

Design-based Classification

Luer Lock Syringes: These syringes have a threaded tip that securely locks the needle in place, reducing the risk of accidental detachment during use.

Slip Tip Syringes: Also known as Luer Slip syringes, they have a smooth tip that allows the needle to slip on and off the syringe easily.

Capacity-based Classification

Low Capacity Syringes: These syringes typically have a capacity of 1 mL or less and are used for precise and small-volume injections.

Standard Capacity Syringes: These syringes have a capacity ranging from 2 mL to 60 mL and are commonly used for general medical procedures.High Capacity Syringes: These syringes have a capacity greater than 60 mL and are used for specific medical procedures, such as irrigation or aspiration of large volumes of fluid.

Safety-based Classification

Safety Syringes: These syringes include additional features to minimize the risk of needlestick injuries, such as retractable needles or needle shields.

Specialty-based Classification

Oral Syringes: These syringes are designed specifically for administering medications orally, particularly for infants, young children, or patients with difficulty swallowing.

Irrigation Syringes: These syringes have a large capacity and are used for flushing wounds or cavities with irrigation solutions.

Catheter Tip Syringes: These syringes have a specialized tip designed for attaching to catheters for various medical procedures, such as drainage or irrigation.

The three important components of a syringe - needle, barrel and piston - together make up an efficient, safe and comfortable injection experience. The needle's sharpness and anti-drip device reduce pain and the risk of cross-infection. The transparent material of the barrel and precise graduation lines enable medical staff to accurately measure and control the amount of medicinal liquid injected. The optimized design of the piston improves the smoothness and accuracy of injection. As technology continues to advance, we can expect syringes to play an even more important role in future innovations, providing patients with a better medical experience.

Understanding the core components of a syringe is crucial for healthcare professionals and medical manufacturers alike. The needle, barrel, and piston work together to ensure accurate medication delivery, dosage control, and patient safety. By using high-quality materials and incorporating innovative features, our modern factory aims to produce syringes that meet the stringent requirements of the healthcare industry. We remain committed to providing reliable and efficient disposable medical equipment for the benefit of patients and healthcare providers worldwide.

Quick Response within 24 hours!

Tel: (+)86-519-88168398

WhatsApp: +86-13961432323

Email: sale01@lelun.com

HengShanQiao Town, out of East Gate, Changzhou ,Jiangsu, China

Changzhou Medical Appliances General Factory Co., Ltd. was built in 1988, it is a modern factory specialized in producing the disposable medical appliances in China. The factory is only 1km to Hengshan entrance of Huning high-speed road and is about 20 miles to Changzhou airport. So the traffic is convenience.

The area of the factory is 40000㎡, the area of purifying workshop is 7000m, and fixed assets are about 5,000,000USD. Our main products are Disposable infusion sets, Disposable blood transfusion sets, Disposable Sterile syringe sets, latex glove, disposable infusion set, simple oxygen mask, nebulizer mask, urine cup, hernia mesh, urine bag etc. Now we can manufacture more than 200,000,000 sets per year.