Basic Info.

Model NO.: 1ML -60ML

Application: Medical

Type: Luer slip

Material: Medical grade PP

Volume: 1ML-60ML

Export Markets: Global

Additional Info.

Trademark: LELUN or OEM

Packing: Polybag, Blister

Standard: CE ISO

Origin: China

HS Code: 90183100

Production Capacity: 1000000PCS Per Day

Product Description

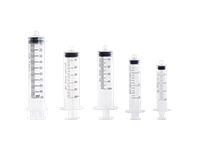

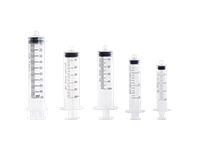

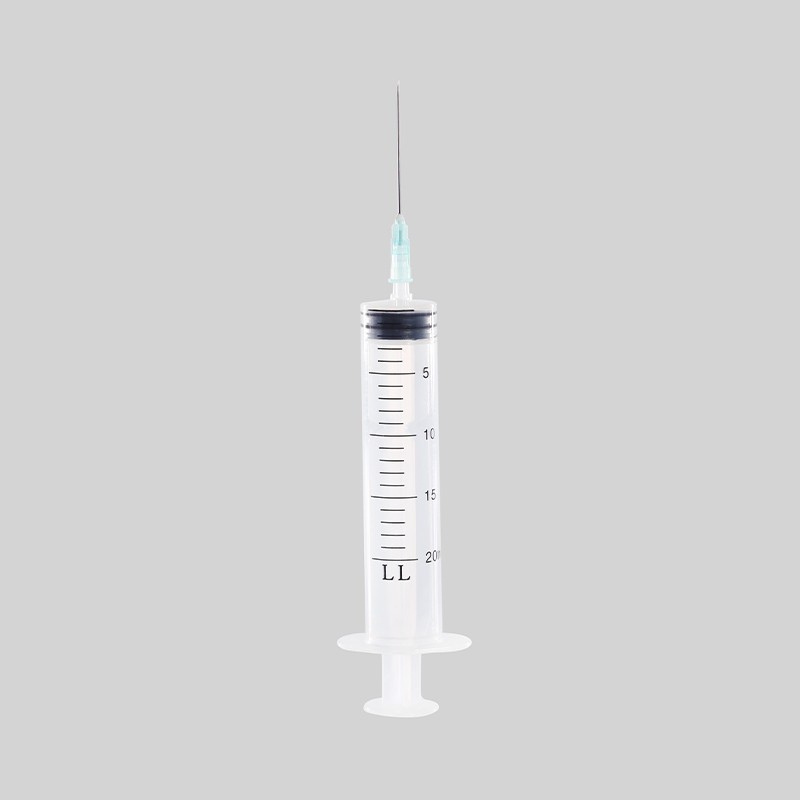

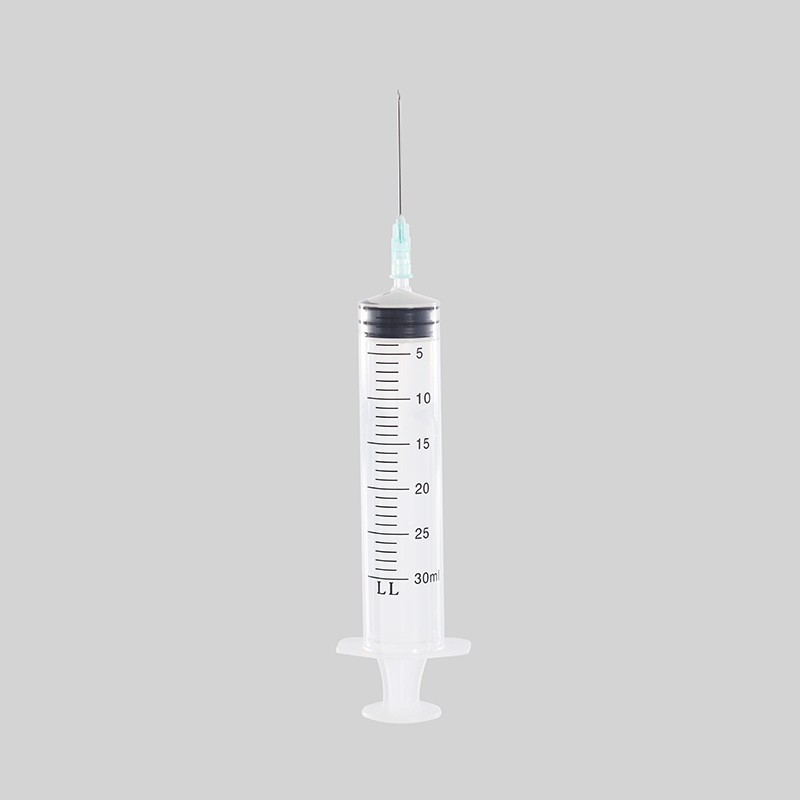

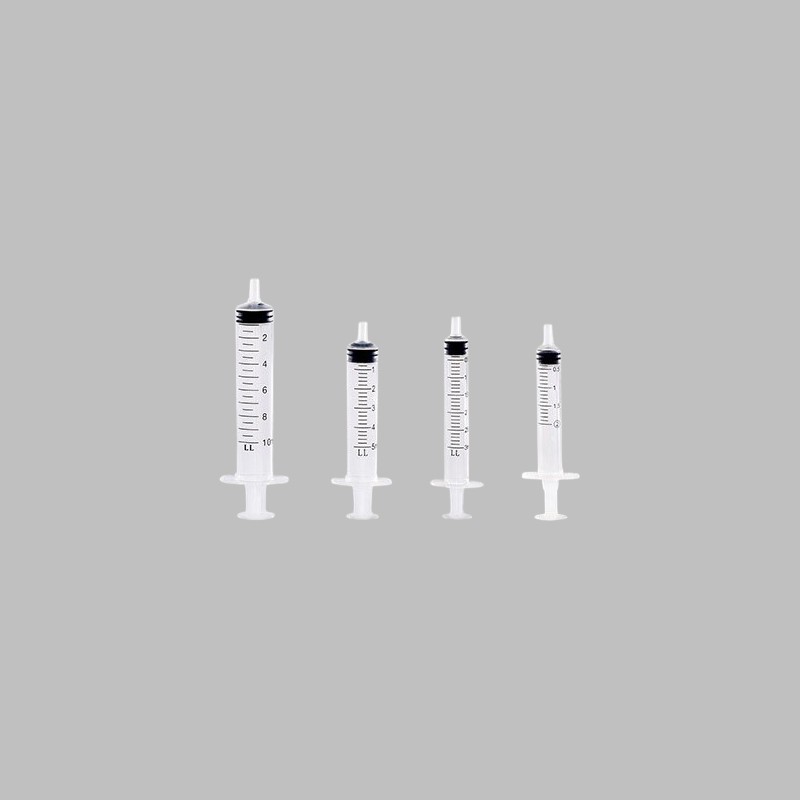

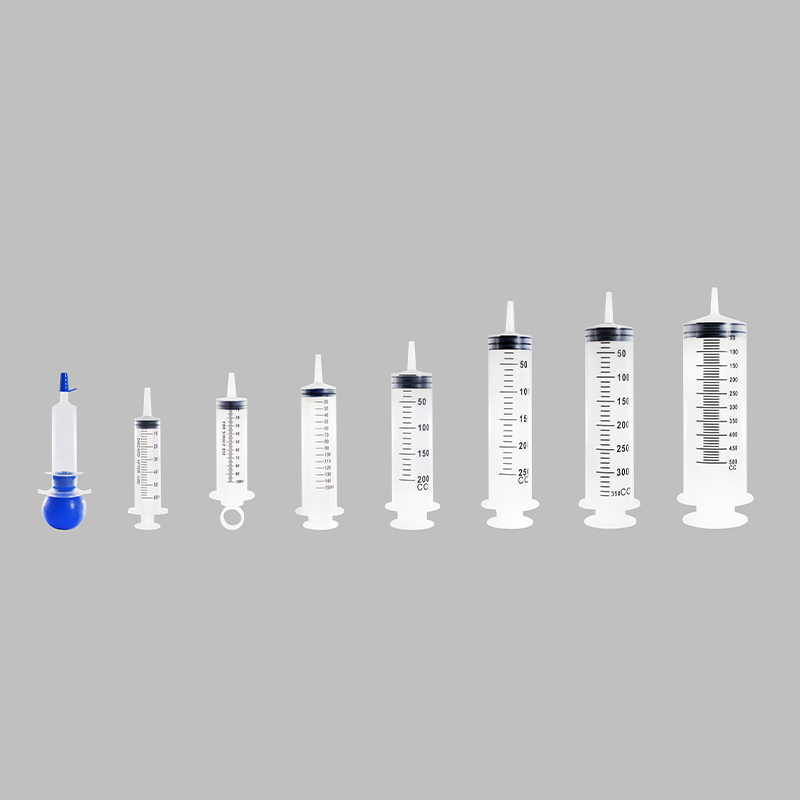

Disposable Syringe:

Features:

1. Size: 1ml, 2ml, 3ml, 5ml, 10ml, 20ml, 30ml, 50ml, 60ml,100ml

2. Material: Made by medical grade PP

3. Needle: With or without needle

4. Piston: Latex or latex free.

5. Luer type: Luer slip

6. Sterile: EO gas steriled, pyrogen-free

7. Packing: PE / Blister individual package, middle polybag or box

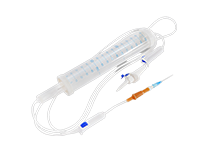

Luer lock manufacturers play a crucial role in producing high-quality medical devices, including luer lock syringes. Luer lock syringes are widely used in healthcare settings for various applications, such as medication administration, blood collection, and sample transfer.

One commonly manufactured luer lock syringe is the 1ml luer slip syringe. This type of syringe has a luer slip tip, which allows the needle to be pushed onto the syringe without any twisting or locking mechanism. The luer slip design provides quick and easy needle attachment, making it suitable for applications where frequent needle changes are required, such as insulin administration or intramuscular injections. Luer slip syringes are available in different sizes to accommodate various volumes of medications or fluids.

Another commonly manufactured luer lock syringe is the luer lock tip syringe. This type of syringe features a luer lock tip, which has threads on the outside of the tip. It requires the needle or other luer lock-compatible devices to be twisted onto the syringe, ensuring a secure and leak-free connection. Luer lock tip syringes are preferred when a secure attachment is essential, such as during procedures that involve high-pressure injections or when administering medications that require precise dosing.

Luer lock manufacturers ensure that their products meet stringent quality standards and regulatory requirements. They utilize advanced manufacturing processes and quality control measures to produce reliable and sterile luer lock syringes. These manufacturers often work closely with healthcare professionals and industry experts to continuously improve their products and develop innovative solutions to meet the evolving needs of the medical community.